Distributed Fiber Optic Vibration Sensing (DVS) System - Complete Technical Guide

1. What is Distributed Fiber Optic Vibration Sensing (DVS)?

Distributed Fiber Optic Vibration Sensing (DVS) is an advanced optical sensing technology that uses single-mode optical fiber (SMF, G652 recommended) as both the sensing medium and signal transmission carrier. Unlike traditional point-type vibration sensors, DVS realizes continuous, real-time vibration monitoring and positioning along the entire length of the fiber, covering distances up to 60km per channel.

With intrinsic safety (no electrical sparks), strong anti-electromagnetic interference, corrosion resistance, and long-distance detection capabilities, DVS is widely used in industrial monitoring, perimeter security, infrastructure protection, and geological hazard early warning. It can detect, locate, and alarm abnormal vibrations (such as intrusion, excavation, pipeline leakage, and structural damage) in real time, without damaging the monitored objects or affecting normal production.

As a high-performance variant of DVS, Distributed Acoustic Sensing (DAS) shares the same core sensing principle but adds high-precision phase demodulation technology, enabling linear restoration of acoustic and vibration signals for more detailed sensing analysis. Both DVS and DAS systems rely on high-quality optical and electrical hardware to ensure stable and reliable operation — YBPhotonics provides all core hardware components for DVS/DAS systems, with in-stock delivery and customization support.

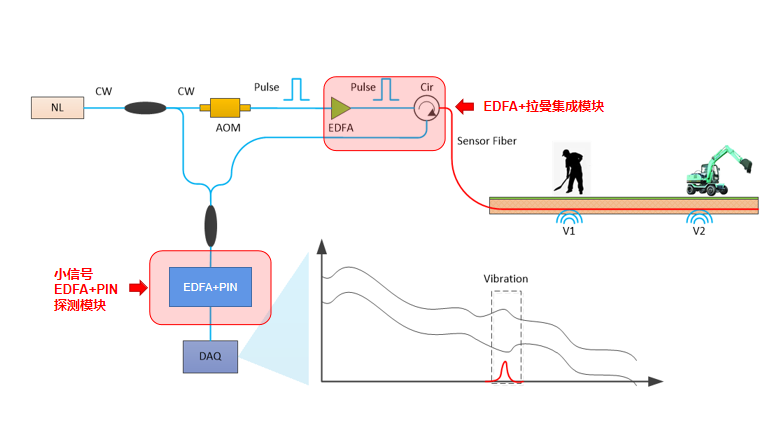

2. How Does the DVS System Work? (Complete Working Principle)

The DVS system operates based on the Rayleigh scattering effect and Phase-Sensitive Optical Time-Domain Reflectometry (φ-OTDR) technology, combined with high-speed signal acquisition and advanced data processing algorithms. The complete working process is divided into 5 key steps, with detailed technical principles as follows:

Step 1: Optical Pulse EmissionThe system’s narrow linewidth laser module emits high-stability, narrow-linewidth optical pulses (typically 3KHz linewidth) with adjustable pulse width and repetition frequency. These optical pulses propagate along the single-mode sensing fiber, and a small portion of the light is scattered at every point along the fiber (this is the Rayleigh scattering effect, a natural characteristic of optical fiber).

Step 2: Vibration-Induced Signal ChangeWhen vibration occurs at any point on the sensing fiber (e.g., illegal intrusion, excavator excavation, pipeline leakage), the physical properties of the fiber at that point change slightly, leading to changes in the intensity, phase, and frequency of the Rayleigh scattered light. The magnitude of the signal change is proportional to the intensity of the vibration.

Step 3: Scattered Light CollectionThe optical circulator (a core component of the DVS system) realizes one-way transmission of optical pulses and collects the scattered light signals that have been changed by vibration. The circulator ensures that the emitted optical pulses propagate forward along the fiber, while the scattered light signals are reflected back to the detection module, avoiding signal interference.

Step 4: Signal Amplification and ConversionThe collected scattered light signals are weak and need to be amplified by an EDFA (Erbium-Doped Fiber Amplifier) or Raman integration module to improve signal-to-noise ratio (SNR). After amplification, the high-SNR detection module (such as APD/PD photodetector) converts the optical signals into electrical signals, which are then transmitted to the data acquisition card.

Step 5: Data Processing and PositioningThe high-speed DAQ (Data Acquisition) card collects the electrical signals in real time (sampling rate up to 100MSps) and transmits them to the upper computer. The upper computer uses built-in algorithms (such as exponential amplification, filtering, power statistics, and phase demodulation) to analyze the signals, calculate the time difference between the emitted pulse and the scattered light signal, and finally determine the exact position of the vibration point (positioning accuracy up to 5m) and issue an real-time alarm.

Core Principle SummaryThe DVS system uses the fiber itself as a "sensor network" to achieve distributed continuous monitoring. The key to its performance lies in the quality of core hardware components — high-stability narrow linewidth lasers, low-noise detection modules, high-speed DAQ cards, and high-isolation optical circulators directly determine the detection distance, positioning accuracy, and signal-to-noise ratio of the system.

3. Key Technical Characteristics of DVS System

| Parameter Name | Performance Indicators |

|---|---|

| Fiber Type | Single-mode fiber G652 |

| Number of channels | 1/2 |

| Detecting the length of fiber optic cable | 40/60KM / Channel |

| Link Loss Tolerance | 10dB |

| Signal-to-noise ratio | >=4dB |

| Frequency Response Range | 40KM,5Hz-1000Hz(Detection distance related) |

| Positioning accuracy | 5m |

| Operating temperature | -10°C-55°C |

| Working humidity | <90%RH |

| Response time | <1s |

- Intrinsic Safety: Pure optical sensing, no electrical components in the sensing fiber, no electrical sparks, suitable for explosive environments (oil/gas refineries, chemical plants).

- Anti-Interference: Quartz fiber material, full electromagnetic insulation, no impact from lightning, strong electromagnetic fields, or high-voltage equipment.

- Anti-Destruction: The fiber section before the breakpoint remains operational after fiber damage, with high anti-destruction performance.

- Easy Deployment: Armored fiber with high compression and tensile strength, support for fence, buried, and pipeline laying methods, simple construction and maintenance.

- Unattended Operation: Supports 7×24h continuous monitoring, SMS/network anomaly alerts, and open data interface for easy integration with monitoring platforms.

4. Typical Applications of DVS System

DVS systems are widely used in various industries worldwide, relying on their long-distance, distributed, and high-reliability characteristics. Below are the most common typical applications, combined with the core hardware requirements of each scenario:

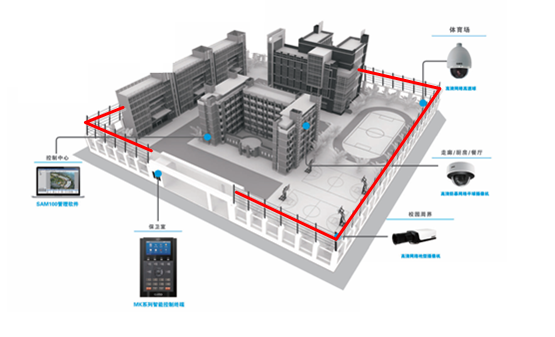

4.1 Perimeter Intrusion Protection- Application Scenarios: Oil/gas refineries, power plants, prisons, museums, airports, military bases, border lines, villa communities.

- Monitoring Objectives: Illegal intrusion, climbing, cutting, and other abnormal behaviors.

- Hardware Requirements: High-sensitivity detection module, 20-40km detection distance integrated module, fast response DAQ card.

- Application Scenarios: Underground utility tunnels, cable trenches, subway tunnels, high-speed rail tracks, roadbeds.

- Monitoring Objectives: Illegal construction (excavator excavation, pile driving), structural damage, and pipeline deformation.

- Hardware Requirements: Long-distance (40-60km) EDFA/Raman integration module, high-precision positioning DAQ card.

- Application Scenarios: Onshore/offshore oil/gas pipelines, water pipelines, chemical pipelines.

- Monitoring Objectives: Illegal drilling, perforation theft, pipeline leakage, and pipeline corrosion.

- Hardware Requirements: Corrosion-resistant industrial-grade hardware, DAS integrated module (for acoustic signal restoration), buried fiber-adapted components.

- Application Scenarios: Landslide-prone areas, roadways, mines, and other geological hazard points.

- Monitoring Objectives: Ground subsidence, landslide, and collapse early warning.

- Hardware Requirements: High-stability laser module, low-noise detection module, 24/7 continuous operation hardware.

- Application Scenarios: Communication fiber optic cable lines, power fiber lines.

- Monitoring Objectives: Line damage, illegal cutting, and signal interruption.

- Hardware Requirements: Low-power integrated module, fast response system, remote monitoring support.

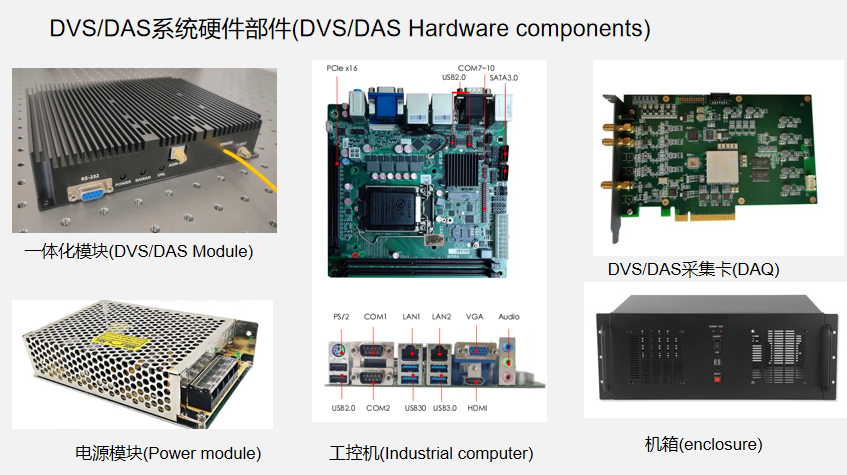

5. Core Hardware Components of DVS/DAS System (YBPhotonics Supply)

| Module Images | Product Name | Model and Description |

|---|---|---|

|

Fiber optic vibration monitoring DVS integrated module | Distance: 20km/40km, Number of channels: 1; DVS integrated module integrates 3K narrow linewidth fiber laser, AOM acousto-optic modulator, pulsed EDFA, optical circulator, Raman amplifier, high signal-to-noise ratio detection module, only need to match a high-speed data acquisition card to form a set of DVS distributed vibration measurement system |

|

DAS Fiber Optic Acoustic Monitoring Module | Distance: 20km/40km, Number of channels: 1; DAS integrated module integrates a 3K narrow linewidth fiber laser, AOM acousto-optic modulator, pulsed EDFA, optical circulator, Raman amplifier, high signal-to-noise ratio detection module, only need to match a high-speed data acquisition card to form a set of DAS distributed acoustic monitoring system |

|

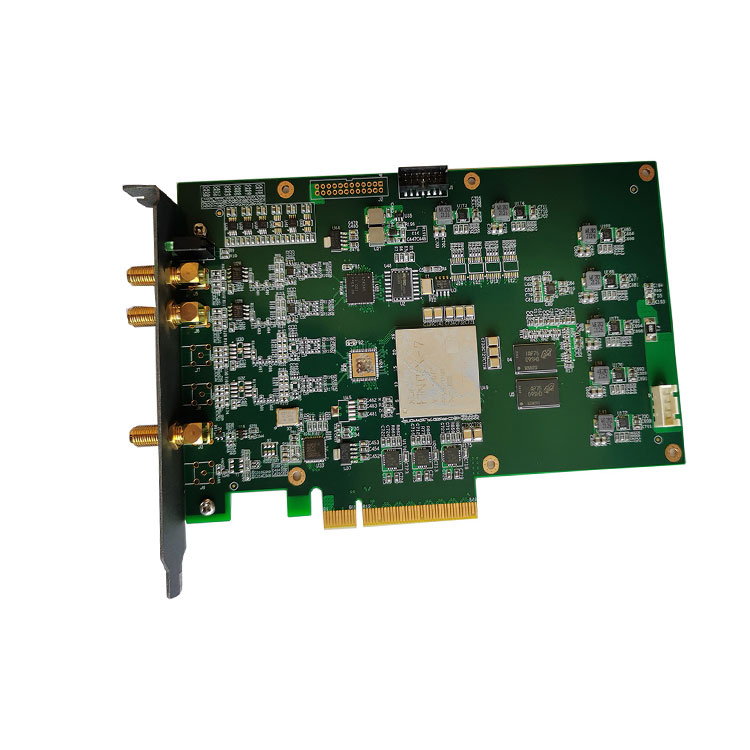

High-speed data acquisition card for DVS | 100MSps sampling rate, 14bits, DVS dedicated capture card with exponential amplification, averaging, filtering, power statistics and other algorithms |

|

Distributed fiber optic vibration DVS/DAS hardware all-in-one | The DVS/DAS hardware all-in-one is the hardware part of the distributed fiber optic vibration sensing system. All hardware is integrated into a 3U case, except for laying the detection cable in the field, so the user only needs to purchase a fiber optic cable; then you can focus on the software development of the sensing system. |

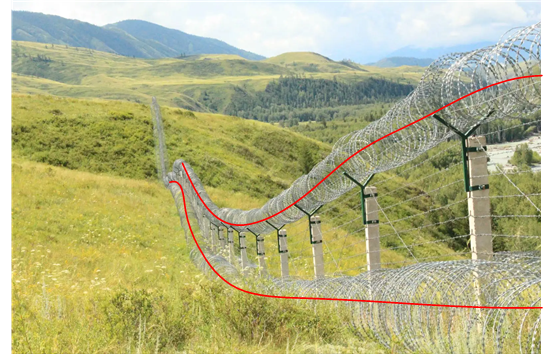

6. Fiber Cable Laying Methods for DVS System

The DVS system consists of a hardware host and sensing fiber. The laying method of the sensing fiber is customized according to the on-site monitoring environment, which directly affects the monitoring effect. The recommended fiber type is armored single-mode G652 fiber (wear-resistant, corrosion-resistant, suitable for outdoor use). The main laying methods are as follows:

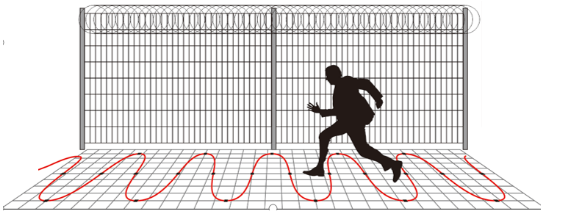

Figure 1, fence laying

When the deployment environment is in the way of a fence, our sensing fiber can be laid in this zigzag pattern. As shown in Figure 1 above.

Figure 2 Buried laying

7. FAQs About DVS System & Core Hardware

Q1: What is the difference between DVS and DAS systems?A: The core difference lies in signal demodulation capability. DVS captures vibration signals and realizes accurate positioning, without linear acoustic signal restoration; DAS supports high-precision phase demodulation, enabling linear restoration of acoustic/vibration signals for more detailed analysis. Both systems use the same core hardware, and YBPhotonics provides hardware for both DVS and DAS systems.

Q2: What fiber type is suitable for DVS systems? Do I need to use special fiber?A: No special fiber is required. The DVS system is compatible with standard single-mode G652 fiber (the most common communication fiber), which can reduce your deployment cost. For harsh environments (outdoor, underground), we recommend using armored single-mode fiber for better protection.

Q3: Can the DVS system be customized according to my specific needs?A: Yes. We support full customization of the DVS system’s detection distance (20km/40km/60km), number of channels (1/2), and frequency response range. The customization is realized by adjusting the parameters of core hardware (laser, EDFA, DAQ card), and we provide free customization consultation.

Q4: What is the lead time for DVS core hardware?A: Over 90% of standard hardware models (integrated modules, DAQ cards, lasers) are in stock for immediate delivery. Customized hardware requires a 2-3 week lead time. You can contact us to check the stock status of specific models.

Q5: Do you provide technical support for DVS system integration?A: Yes. We offer free professional technical guidance for DVS system integration, including hardware wiring, parameter matching, upper computer software connection, and on-site debugging. Our technical team provides 8/5 online support to solve your integration problems.

Q6: Is global shipping available for DVS hardware, and is the shipping cost included?A: We provide worldwide shipping to all countries/regions (including the United States, Europe, Southeast Asia, etc.). The shipping cost is included in the product price, with no extra fees. We use reliable international logistics (DHL, FedEx) to ensure fast and safe delivery.

Q7: How to ensure the stability of the DVS system in harsh environments?A: All our DVS core hardware adopts industrial-grade design, with wide operating temperature range (-10℃~55℃), corrosion resistance, and anti-electromagnetic interference. We also provide protective accessories for hardware and fiber, ensuring stable operation in outdoor, humid, and corrosive environments.

8. Contact Us for DVS System Hardware Inquiries

If you are looking for DVS/DAS system core hardware, need customization support, or have questions about DVS system principles and deployment, please contact us directly. Our professional team will provide you with detailed technical consultation and product quotations.

Email: Hqy@ybphotonics.com

WhatsApp: +86-13427781756

Business Scope: DVS/DAS core hardware supply, hardware customization, technical integration guidance, free product manual and test data.

Global Service: In-stock fast delivery, free worldwide shipping, 24/7 technical support, 1-year product warranty.